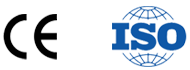

The manually operated butt fusion machine is featured by easy use, lightweight and quick operation.

Butt Fusion Machine

Featuring a compact design, robust power, and simplified maintenance, RIYANG hydraulic butt fusion machines are widely used in municipal works, mining, gas networks, and agricultural irrigation projects involving pipe fusion.

Download the file

Download the file

performance

Products Comparison

V160-V355 | V450-V630 | V800-V1200 | V1600-V3000 | |||

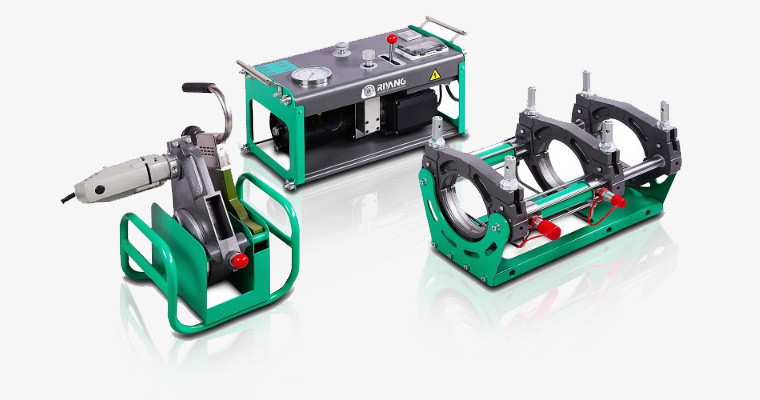

| The open-frame HPU design provides convenient access for maintenance | √ | √ | √ | |||

| Data logger compatible | √ | √ | √ | √ | ||

| Hydraulic unit encased by detachable frame, easier maintenance and repair | √ | √ | √ | |||

Accurate and maintenance-free gauge showing the welding pressure | √ | √ | √ | |||

USB charging port ready for your mobile device | √ | √ | √ | |||

Cylinders with both low and high force options are available for increased versatility | √ | √ | √ | √ | ||

ISO inserts, IPS inserts, DIPS inserts available | √ | √ | √ | √ | ||

The narrow jaws facilitate fusion of flanges, outlet branches of tees, and a wide range of fittings | √ | √ | √ | |||

The conversion from a 4-jaw to a 3-jaw carriage is designed for working in tight spaces | √ | √ | √ | √ | ||

The conversion from a 3-jaw to a 2-jaw carriage is designed for working in tight spaces | √ | √ | ||||

Aluminum upper and bottom clamp | √ | √ | ||||

The heating plate is equipped with interchangeable heating elements | √ | √ | √ | √ | ||

Reviews

Testimonials

Model: V800

“Very good machine, excellent alignment, heating plate heats up fast and keeps constant”

Model: V800

“We used it for special stub end fusion operations for our pipe lining work. The machine worked very well.”

Model: V630

“The function is very good. This is the first time to use Riyang fusion machine, before we used the equipment from Italy.”

Model: V1200

“The Riyang V1200 is a reliable and efficient machine, offering smooth operation and precise welding.”

faq

Frequently Asked Questions

SOLUTIONS

Explore Industry Application Solutions

Municipal Water Supply Systems

Learn More

Natural Gas Distribution Networks

Learn More

Mining Industry Pipelines

Learn More

Pipe Fittings Fabrication

Learn More

Industrial Process Pipelines

Learn More

Need Assistance? Contact Us!

We're here to help with tailored solutions for all your plastic welding needs.

- Free Technical Consultation

- Product Guidance

- Fast, Reliable Support

Big Pipes, Big Solutions!

Need reliable pipe fusion equipment for large-diameter pipe projects? Our heavy-duty pipe fusion welding machines are for the job—strong, precise, and ready to perform.

WE ARE WILLING TO TAKE YOUR CHALLENGEBecome Our Distributor!

Join Riyang family as a distributor and support infrastructure development worldwide.

- Exclusive Products

- Training & Support