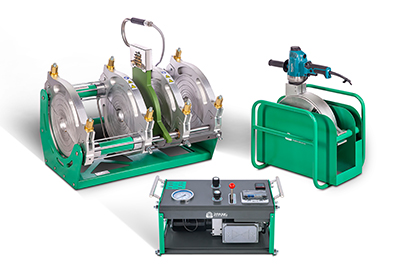

The manually operated butt fusion machine is featured by easy use, lightweight and quick operation.

Mining Pipelines

Solutions

The Solutions We Offer

High Pressure

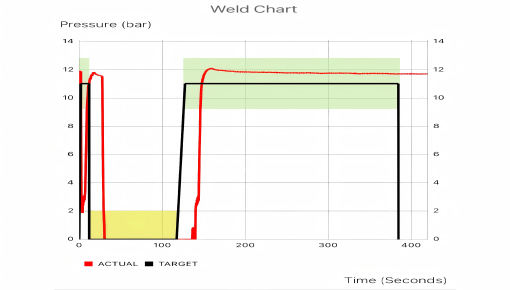

In strict accordance with international welding standards such as ISO 21307, and ASTM F2620, ensuring the quality and safety of the welded joints.

Data Logging

Recording welding data ensures traceability and quality assurance

Easy-To-Use Of One Button

The simple operation minimizes the operational errors that inexperienced operators may cause.

products

Recommended Products

- Model:

- V315SHP

- Range in mm:

- 90mm-315mm

- Range in inch:

- 3"IPS - 12" IPS

- Application:

- Butt Fuse

- Model:

- ARMOR1200i

- Range in mm:

- 630mm-1200mm

- Range in inch:

- 24"IPS - 48" IPS

- Application:

- Butt Fuse

- Model:

- ARMOR355i

- Range in mm:

- 110mm-355mm

- Range in inch:

- 4"IPS - 14" IPS

- Application:

- Butt Fuse

Riyang Case

Read Our Success Stories

Machine Model: ARMOR 48i

Location: Monterey, Mexico

ChallengesBefore Using the ARMOR 48i

Harsh Terrain Mobility Issues:

Rugged mining sites required equipment that could traverse uneven ground efficiently.

High-Pressure Welding Failures:

Traditional machines couldn’t maintain joint integrity under extreme mining pipeline pressures.

Manual Pipe Alignment And Clamping Inefficiency:

Human adjustments during clamping and alignment led to misaligned welds and rework, wasting time.

Budget Constraints for Advanced Equipment:

Competing high-pressure welding systems were prohibitively expensive.

SolutionsOffered by RIYANG ARMOR 48i

Trailer-Mounted Mobility

Trailer-mounted design allows easy relocation across rugged terrain, ensuring operational flexibility on mining sites.

High-Pressure Welding

The automatic welding system meets ASTM F2620-20 standards, ensuring reliable, high-strength joints under pressure.

Full Hydraulic Clamping

Automated pipe alignment and clamping enhance precision, reduce manual effort, and improve welding quality.

Key Benefits Experienced

50% Faster Site Mobility

Reduced equipment relocation time from hours to minutes.

Zero Pressure-Related Failures

All welds withstood mine operational stresses without leaks.

15% Material Waste Reduction

Precise alignment minimized pipe trimming and rework.

ROI Within 8 Months

Lower upfront costs and higher efficiency provided rapid payback.

Features

Why Choose Us

High-Pressure Automatic Welding

The ARMOR series ensures reliable performance for welding larger pipes in heavy-duty mining projects with high-pressure application features.

Compliance with ASTM F2620-20

The ARMOR Series complies with international safety standards and provides at least a 40% increase in weld efficiency while maintaining weld quality.

Portability and Convenience

The ARMOR 48i model’s trailer design enables easy transport and setup in remote mining locations.

Affordable Pricing with High ROI

Offering high-end features at a competitive price, the ARMOR 48i delivers exceptional ROI and cost-effectiveness compared to similar machines.

Looking for Something Specific?

Need Assistance? Contact Us!

We're here to help with tailored solutions for all your plastic welding needs.

- Free Technical Consultation

- Product Guidance

- Fast, Reliable Support

Big Pipes, Big Solutions!

Need reliable pipe fusion equipment for large-diameter pipe projects? Our heavy-duty pipe fusion welding machines are for the job—strong, precise, and ready to perform.

WE ARE WILLING TO TAKE YOUR CHALLENGEBecome Our Distributor!

Join Riyang family as a distributor and support infrastructure development worldwide.

- Exclusive Products

- Training & Support