The manually operated butt fusion machine is featured by easy use, lightweight and quick operation.

Pipe Fitting Fabrication

Solutions

The Solutions We Offer

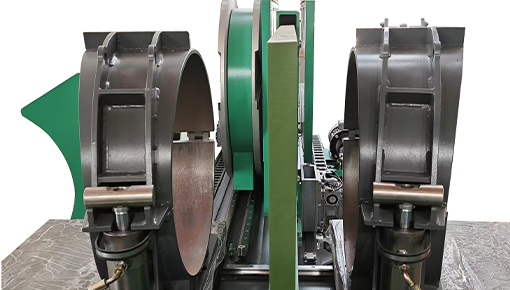

High Synchronization

High synchronization ensures consistent bead height, guaranteeing the joint quality.

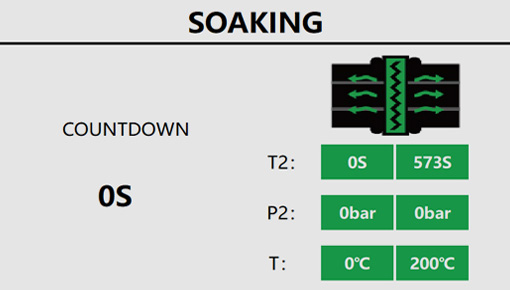

Automation

Automated fusion welding process eliminates errors caused by manual operations.

Remote Troubleshooting

Remote fault diagnosis and troubleshooting enhance after-sales service efficiency, significantly reducing machine downtime.

products

Recommended Products

- Model:

- ATLA400

- Range in mm:

- 90mm-400mm

- Range in inch:

- 3"IPS - 14" IPS

- Application:

- Fittings Fabrication

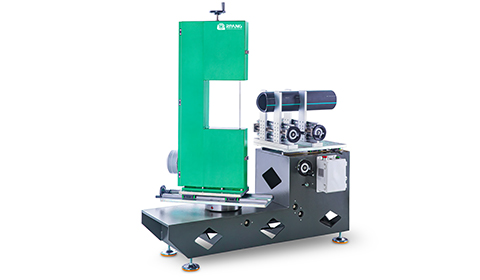

- Model:

- ATLA630CNC

- Range in mm:

- 315mm-630mm

- Range in inch:

- 12"IPS - 24" IPS

- Application:

- Fittings Fabrication

- Model:

- ARC315

- Range in mm:

- 32mm-160mm

- Range in inch:

- 1"IPS - 6" IPS

- Application:

- Radius Cutting

- Model:

- TPS630

- Range in mm:

- 200mm-630mm

- Range in inch:

- 8"IPS - 24" IPS

- Application:

- Angular Cutting

Riyang Case

Read Our Success Stories

Machine Model: ATLA630CNC, TPS630

Location: Dubai, UAE

ChallengesBefore Using the ATLA630CNC

Precision Issues in Multi-Angle Welding:

Previously, achieving consistent and precise angles for HDPE fittings like Wyes and tees was a challenge. Manual adjustments often resulted in minor errors, leading to material wastage and rework.

Low Production Efficiency:

The manual welding process we used was time-consuming, especially for larger fittings. This slowed down our production cycle and delayed order fulfillment.

Limited Automation:

The lack of automation meant that operators had to monitor and adjust the welding process continuously, which increased labor costs and reduced overall efficiency.

Consistency in Welding Quality:

Maintaining consistent quality across batches was difficult, as manual operations were prone to variability in welding parameters, leading to occasional quality issues.

SolutionsOffered by RIYANG's ATLA630CNC

Enhanced Precision and Automation

The ATLA630CNC features a low working bed height, a compact structure, and high strength, making it easier to change clamps types and adjust clamps angles. Additionally, the machine remains deformation-free even under high pressure during large pipe welding. The automation of the welding process ensures precise control of pressure, time, and temperature.

Streamlined Production Process

The machine's ability to automate the welding process has drastically reduced production times. The cutting saw TPS630 stands out with its wide cutting range of -45° to 67.5°. When manufacturing components for wye fittings, the cutting angle can be easily adjusted by rotating the saw twice, greatly improving cutting efficiency.

Ease of Operation

With its intuitive interface and advanced automation features, our operators were able to quickly adapt to the ATLA630CNC. The training provided by RIYANG further ensured a smooth transition.

Key Benefits Experienced

Increased Productivity

The ATLA630CNC has increased our overall production capacity by 40%, enabling us to meet growing demand without compromising on quality.

Cost Savings

By reducing material wastage and labor dependency, the machine has helped us lower production costs by approximately 20%.

Enhanced Flexibility

We can now produce a wider variety of fittings, from small elbows to large-diameter Wyes, without the need for multiple machines or extensive setup changes.

Stronger Market Competitiveness:

The high-quality fittings produced using the ATLA630CNC have strengthened our reputation in the market, leading to an increase in repeat customers and new contracts.

Features

Why Choose Us

Precision and Flexibility

The ATLA series provides more accuracy to fabrications of HDPE/PP fittings like elbow, tee, cross and wye, according to the standards DVS2207-1/11, ISO21307, ASTM F2620 and others.

Enhanced Efficiency

With advanced automation, the ATLA series reduces production time, increasing output while maintaining high quality. The machine supports both low and high-pressure welding systems for versatile use.

Consistent Quality

The ATLA series delivers reliable, high-quality welds with uniform pressure and temperature control, ensuring minimal defects and fewer quality checks, resulting in higher customer satisfaction

Easy to Operate

Designed for ease of use, the ATLA series has an intuitive interface that simplifies setup and operation, reducing training time and downtime while maximizing productivity.

Looking for Something Specific?

Need Assistance? Contact Us!

We're here to help with tailored solutions for all your plastic welding needs.

- Free Technical Consultation

- Product Guidance

- Fast, Reliable Support

Big Pipes, Big Solutions!

Need reliable pipe fusion equipment for large-diameter pipe projects? Our heavy-duty pipe fusion welding machines are for the job—strong, precise, and ready to perform.

WE ARE WILLING TO TAKE YOUR CHALLENGEBecome Our Distributor!

Join Riyang family as a distributor and support infrastructure development worldwide.

- Exclusive Products

- Training & Support