The manually operated butt fusion machine is featured by easy use, lightweight and quick operation.

Industrial Pipelines

Solutions

The Solutions We Offer

High Versatility

The versatile design greatly accommodates specialized working scenarios.

Customizable Welding

Customizable welding parameters tailored to non-standard pipes used in the project.

Data Logging

Recording welding data ensures traceability and quality assurance

products

Recommended Products

- Model:

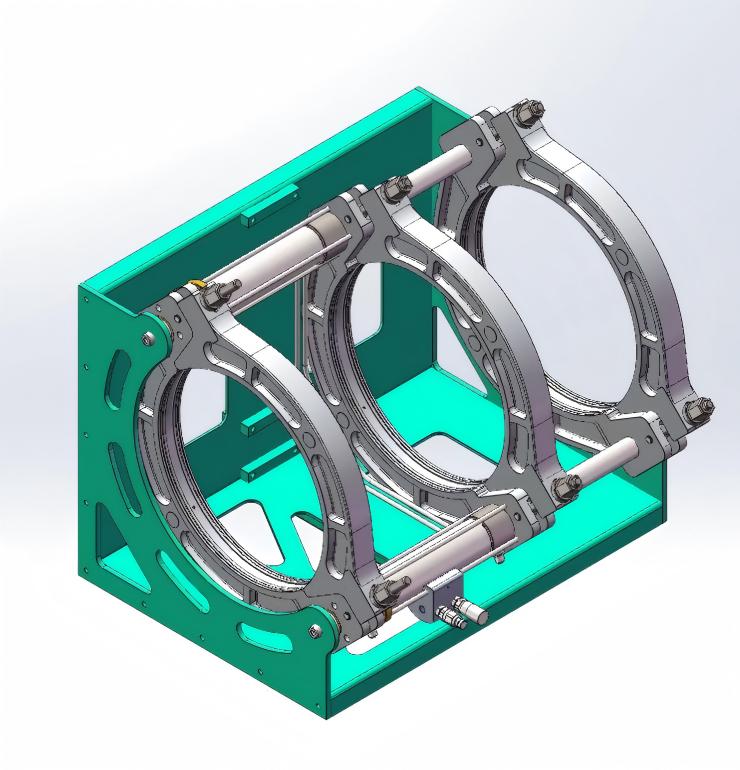

- V630CNC

- Range in mm:

- 315mm-630mm

- Range in inch:

- 12"IPS - 24" IPS

- Application:

- Butt Fuse

- Model:

- RRQ-160TD

- Range in mm:

- 50mm-160mm

- Range in inch:

- 2"IPS - 6" IPS

- Application:

- Socket Fuse

- Model:

- ATLA400

- Range in mm:

- 90mm-400mm

- Range in inch:

- 3"IPS - 14" IPS

- Application:

- Fittings Fabrication

Riyang Case

Read Our Success Stories

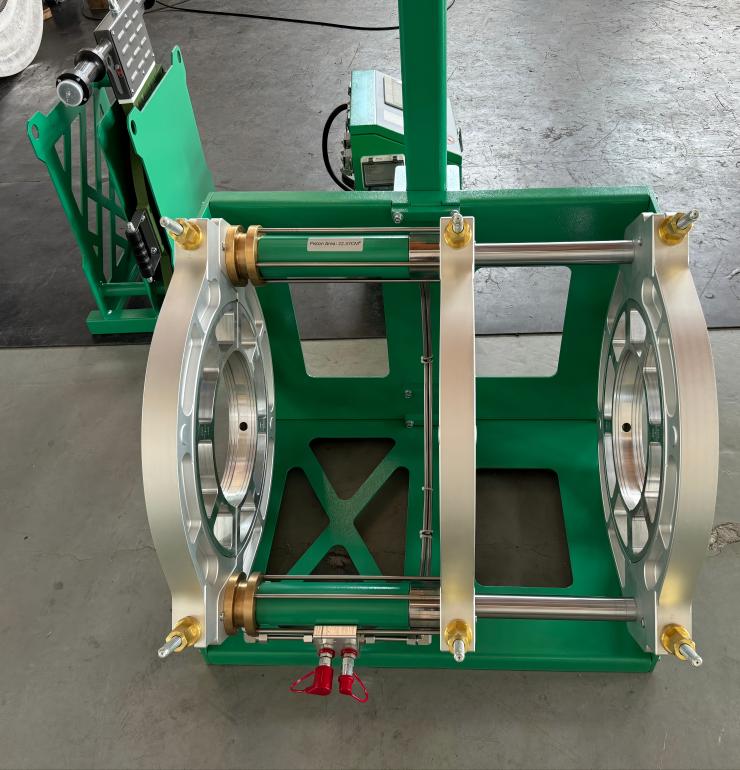

Machine Model: FLEX630CNC

Location: Busan, Korea

ChallengesBefore Using the FLEX630CNC

Hydrogen Leak Risks:

Manual fusion welding machine couldn’t achieve airtight seals for explosive hydrogen transport.

Material Damage During Welding:

Specialized plastics require ultra-precise temperature control to avoid degradation.

Manual Data Tracking Bottlenecks:

Lack of automated logs complicated QA/QC for safety-critical hydrogen systems.

Inflexible Automation Integration:

Legacy machines couldn’t interface with robotic arms, limiting production scalability.

SolutionsOffered by RIYANG FLEX630CNC

Precision Welding for Safety

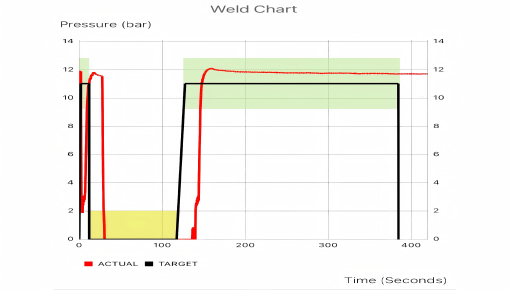

Advanced CNC control ensures precise temperature and pressure regulation, achieving robust, leak-proof welds required for hydrogen transport.

Optimized Compatibility with Plastic Pipes

The machine's settings are tailored for specialized industrial plastic pipes, minimizing material waste and ensuring strong, reliable joints.

Seamless Automation Integration

The FLEX630CNC integrates effortlessly with robotic systems, streamlining pipe handling and improving overall production efficiency.

Key Benefits Experienced

50% Weight Reduction

The transition from steel to welded plastic pipes halved transport energy costs.

30% Faster Production Cycles

Robotic integration enabled 24/7 manufacturing with minimal downtime.

0% Defect Rate

100% burst test pass rate validated weld integrity.

Simplified Audits

Digital weld logs reduced certification time by 40%.

Features

Why Choose Us

Precision Welding Control

RIYANG's CNC-controlled systems maintain micron-level accuracy in temperature, pressure, and time parameters, ensuring leak-proof joints for hydrogen transport and other safety-critical industrial pipelines.

Tailored Machine Solutions

From manual to fully automatic systems, we provide customizable welding machines aligned with your budget and production scale. Our modular design allows seamless upgrades to higher automation levels as needs evolve.

Engineered for Durability

Rigorously tested under high-pressure and heavy-duty conditions, our machines deliver unmatched reliability in mining and industrial environments, backed by ISO-compliant quality control processes.

Future-Ready Upgradability

Invest confidently – our modular architecture enables cost-effective expansions, protecting your initial investment while adapting to emerging industry demands.

Looking for Something Specific?

Need Assistance? Contact Us!

We're here to help with tailored solutions for all your plastic welding needs.

- Free Technical Consultation

- Product Guidance

- Fast, Reliable Support

Big Pipes, Big Solutions!

Need reliable pipe fusion equipment for large-diameter pipe projects? Our heavy-duty pipe fusion welding machines are for the job—strong, precise, and ready to perform.

WE ARE WILLING TO TAKE YOUR CHALLENGEBecome Our Distributor!

Join Riyang family as a distributor and support infrastructure development worldwide.

- Exclusive Products

- Training & Support