The manually operated butt fusion machine is featured by easy use, lightweight and quick operation.

Municipal Water Pipeline

Solutions

The Solutions We Offer

High Versatility

Compact design ensures ease of operating the fusion machine in ditch or other confined working environments.

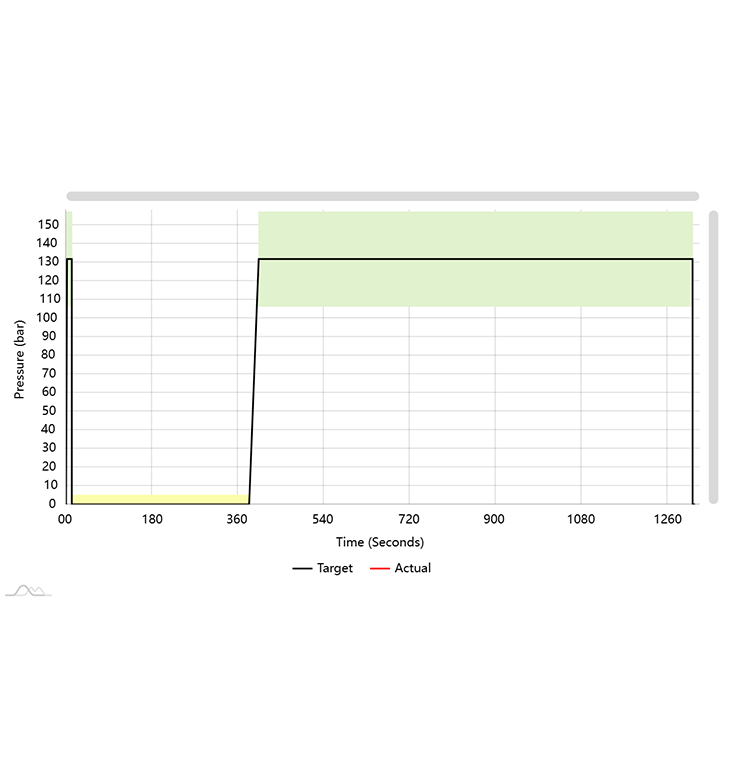

Data Logging

Recording welding data ensures traceability and quality assurance.

Efficient mobility

Efficient mobility enhances flexibility, reduces downtime, and ensures seamless operation across various work sites.

products

Recommended Products

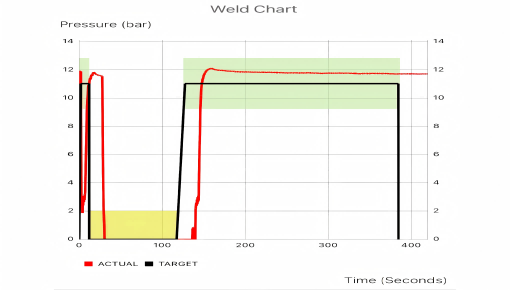

- Model:

- V630

- Range in mm:

- 315mm-630mm

- Range in inch:

- 12"IPS - 24" IPS

- Application:

- Butt Fuse

- Model:

- V315CNC

- Range in mm:

- 90mm-315mm

- Range in inch:

- 3"IPS - 12" IPS

- Application:

- Butt Fuse

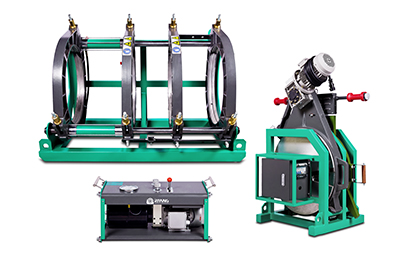

- Model:

- MAMBA 630

- Range in mm:

- 315mm-630mm

- Range in inch:

- 12"IPS - 24" IPS

- Application:

- Support Fused Pipe

Riyang Case

Read Our Success Stories

Machine Model: V1000

Location: Lima, Peru

ChallengesBefore Using Riyang V1000 Butt Fusion Machine

Mobility Limitations in Narrow Trenches:

Traditional HDPE fusion machines were too bulky for tight spaces, making pipe loading/unloading and equipment relocation inefficient.

Weld Quality Concerns for Large-Diameter Pipes:

Previous fusion equipment caused stress concentration at joints, risking leaks and failures in critical water supply pipelines.

Manual Data Recording Inefficiencies:

Traditional fusion machine lacked data recording features, making manual documentation time-consuming and prone to errors during inspections.

Time-Consuming Project Timelines:

Slow welding processes extended project completion times, impacting urban water supply upgrades.

SolutionsOffered by RIYANG V1000

Compact and Modular Design:

The lightweight, easily assembled structure allowed seamless operation in narrow trenches, improving mobility and pipe handling efficiency.

Advanced Welding Technology & Compliance:

With ISO21307 & ASTM F2620-20 compliance, precise temperature and pressure control ensure uniform welds, eliminating joint weaknesses and meeting rigorous safety standards.

Efficient, Data-Driven Welding Process:

The integrated PEWELDBANK Data Logger tracks welding parameters in real time, automating compliance reporting, optimizing workflow, and boosting pipeline installation efficiency by 30%.

Key Benefits Experienced

30% Faster Project Completion

Completed a 6-month water supply project in 4.5 months, meeting urgent urban demand.

Zero Leak Incidents

Welds passed all pressure tests, ensuring the long-term reliability of Lima’s water infrastructure.

Reduced Labor Costs

Automated data logging saved 15% in administrative labor hours, and easily track welding datas remotely.

Enhanced Regulatory Compliance

Digitized weld records streamlined inspections and gained quick municipal approval.

Features

Why Choose Us

Superior Welding Quality

The welding quality of municipal water pipelines directly impacts the stability and safety of the entire water supply system. The V-series fusion welding machines utilize advanced technology and comply with ISO21307 and ASTM F2620-20 high-pressure welding standards.

Compact Design for Tight Spaces

Municipal water pipeline construction often involves working in narrow trenches. The compact design of the V-series fusion welding machine allows easy operation in tight spaces, whether loading/unloading pipes or working in challenging environments, improving efficiency and reducing delays.

Smart Compliance Tracking

The V-series features PeWeldBank functionality that captures real-time welding parameters (temperature, pressure, time) for quality reviews, compliance checks, and post-project technical support.

Cost-Efficient Operations

The V-series butt fusion machine high efficiency and durability reduce frequent repairs and replacements, significantly lowering long-term costs despite a higher initial investment.

Looking for Something Specific?

Need Assistance? Contact Us!

We're here to help with tailored solutions for all your plastic welding needs.

- Free Technical Consultation

- Product Guidance

- Fast, Reliable Support

Big Pipes, Big Solutions!

Need reliable pipe fusion equipment for large-diameter pipe projects? Our heavy-duty pipe fusion welding machines are for the job—strong, precise, and ready to perform.

WE ARE WILLING TO TAKE YOUR CHALLENGEBecome Our Distributor!

Join Riyang family as a distributor and support infrastructure development worldwide.

- Exclusive Products

- Training & Support