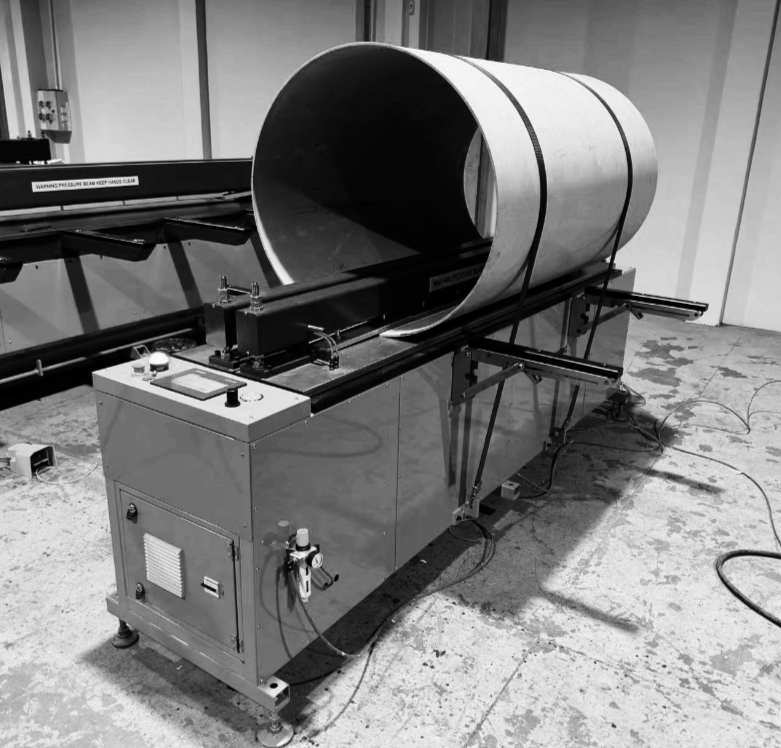

Welding HDPE and PP Sheets with a Butt Welding Machine

Step 1: Preparation

Ensure the welding machine is clean and in proper working condition.

Select the appropriate welding parameters based on the material thickness and type (HDPE or PP).

Prepare the HDPE or PP sheets by cutting them to the desired size and ensuring they are clean and free from contaminants.

Step 2: Set-Up

Place the HDPE or PP sheets to be welded on the welding table, ensuring they are properly aligned.

Adjust the clamping mechanism of the welding machine to securely hold the sheets in place.

Step 3: Heating

Power on the butt welding machine and set the heating element to the recommended temperature for the chosen material (HDPE or PP).

Wait for the machine to reach the desired temperature, ensuring even heating across the welding area.

Step 4: Welding

Once the heating element is at the correct temperature, engage the welding process. The heated element is brought into contact with the HDPE or PP sheets, softening the material.

Apply pressure evenly to fuse the sheets together. The welding time and pressure will depend on the material thickness and type.

Step 5: Cooling

After the welding process is complete, allow the welded joint to cool naturally. Do not rush this step, as it ensures a strong and reliable bond.

Keep the sheets and joint still during the cooling process to prevent distortion.

Step 6: Inspection

Inspect the welded joint for any defects, such as voids, irregularities, or incomplete fusion.

Ensure the welded joint meets the required standards for strength and appearance.

Step 7: Finishing

If necessary, trim any excess material or flash from the welded joint to achieve the desired appearance and dimensions.

Important Considerations:

Always follow the manufacturer's guidelines and recommended settings for your specific HDPE Sheet Butt Welding Machine, PP Sheet Butt Welding Machine, or Plastic Sheet Welding Machine.

Ensure safety measures are in place, including the use of appropriate personal protective equipment (PPE) such as gloves and eye protection.

Welding parameters (temperature, pressure, and time) may vary depending on the machine and material specifications, so refer to the equipment manual for precise instructions.

Proper surface preparation, cleanliness, and alignment are crucial for achieving strong and consistent welds.

Regular maintenance and calibration of the welding machine are essential to ensure its continued performance.

By following these professional guidelines and taking appropriate precautions, you can achieve high-quality welded joints when working with HDPE and PP sheets using a butt welding machine.