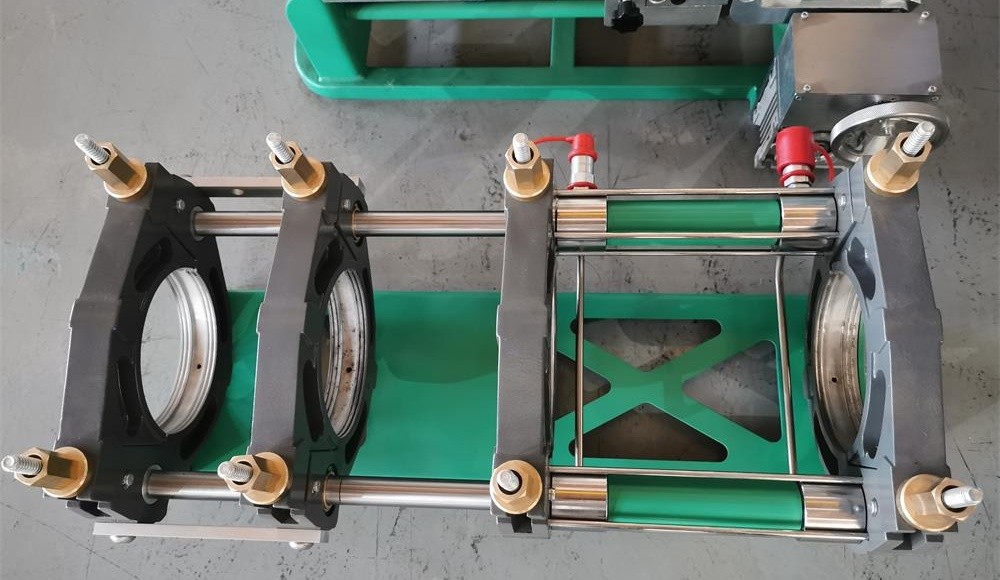

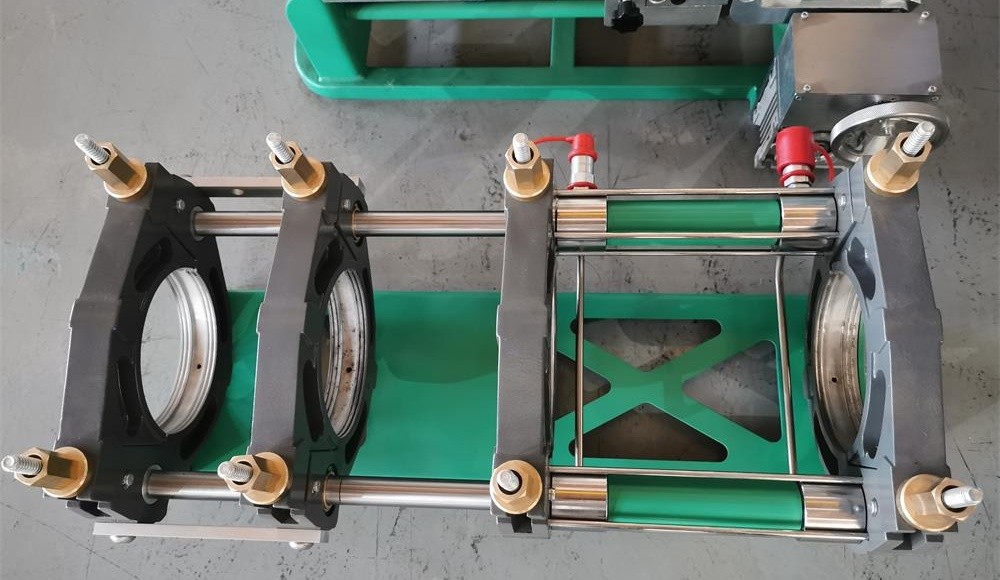

One of the major advantages of using a

butt fusion machine for welding pipes is that there is a range of techniques that can be used to evaluate the quality of welds. This includes simple on-site tests that the welder can perform, nondestructive examination (NDE), and destructive testing in laboratories under reference conditions.

During the formation of a butt fusion joint, an internal and an external weld bead is formed at the location of the joint.

The bead formed on the outside of the pipe can be removed easily with simple mechanical tools and provides a quick and easy means of checking for common problems in welding. The specific methods and steps are as follows.

(1) Before removing it from the pipe, the external weld bead can be visually checked. It should be uniform both in terms of its width and of each side of the bead when viewed around the circumference of the weld. If not, then it would indicate that there most likely is a problem with the heater plate (distorted, or heater elements broken).

(2) The width of the bead can be measured to check it falls between a minimum and maximum width. A bead too small might indicate insufficient heat in the weld, a bead too large may be too much heat or too much pressure during the welding process.

(3) Once removed, the bead can be subjected to bending and twisting along its length. If the bead splits in a brittle fashion then it is likely that the pipe joint also has brittle areas (the bead is representative of the weld quality in the pipe wall). If the bead has brittle-like defects then the pipe joint should be remade.

Nondestructive examination (NDE) of butt fusion welds can be performed and tools are usually very good at detecting voids, or contamination, which may exist in the weld and need to be addressed.

NDE techniques are not routinely used as the industry has very good experience of combining assessment of weld beads, together with a sampling of joints by destructive testing, as the means by which it demonstrates the suitability of the technique. However, for high-risk installations, it may be desirable to specify NDE and one example technique, which was originally funded by the European.

Definitive tests on weld quality can be made by conducting destructive testing. Such tests can be made on construction sites in a simplified form but in case of reference, are conducted in a laboratory.

The purpose of such testing is usually to check that the butt fusion machine that is taken onto the construction site is working properly and that the welds it makes are of the expected quality, so often it is the first weld made on the site that is tested as a minimum.

In the previous article, we talk about the standards that can be specified for this work, usually, the test is one where tensile specimens are cut from the weld and pulled to force failure which can be assessed both quantitatively and qualitatively. RIYANG's website shares a lot of application knowledge about butt welding machines, you can also contact us to get a comprehensive solution.

As an experienced

butt welding machine manufacturer, RIYANG has won unanimous praise from many customers with its excellent R&D technology and leading manufacturing process. In order to strictly control the quality of products, we are equipped with a professional quality inspection system and a comprehensive management team. We always put the needs of customers first, so we can also provide users with effective solutions technology and thoughtful one-stop service. If you want to buy our hot melt butt welding machine, please contact us immediately!