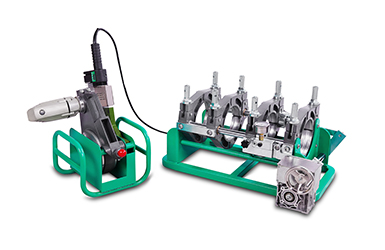

The manually operated butt fusion machine is featured by easy use, lightweight and quick operation.

FUSION PRODUCTS

Compact, Lightweight, And Rugged Machine Designed To Butt Fuse Pipes To Pipes And Fittings.

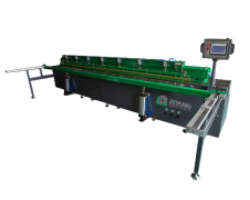

Applied to cutting pipes at different angle and fabricate a variety of plastic fitting.

Suitable for welding thermoplastic sheets made of HDPE, PP, PVC, PVDF.

It could be used to socket weld thermoplastic pipes made of HDPE, PVDF, PP, and PPR.

Electrofusion machine is applied to electro fuse the fittings with plastic pipes.

Pipe welding tools are usually requested when doing butt welding or electrofusion welding.

A variety of plastic welding machines are applied to weld materials, like HDPE, PP, PVDF, PVC, LDPE, etc,

Since 2010, Specialized in Sales and Manufacture of Pipe Fusion Equipments Only

Riyang fusion machine is known for its excellent of engineering, ease of use and the ability to survive in the toughest conditions. Over the years, we have been continuously improving the details and quality of the machine. Before delivery, each machine must pass the "CTBD" inspection process, and all products are designed and manufactured in accordance with international standards and directives (ISO). Many of the original machines are still running in the field.

8 ReasonsPARTNER WITH RIYANG

Each machine fully verified in prior delivery

Continuous developing innovative products

Customized machines available

Professional welding guidance available

Efficient and professional pre-sales service

Claim will be responded within 24hours

Continuous integrating and improving top supply chain network

Priority in cooperating with local professional distributor and supply immediate service

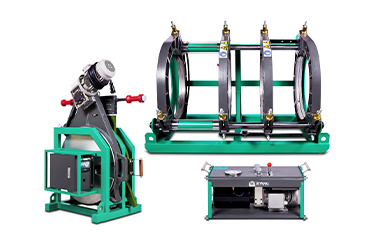

V315 90MM-315MM (3"IPS - 10" IPS)

Robust, durable and stable performance

Small footprint

2 years warranty

V630 315MM-630MM (12"IPS - 24" IPS)

High strength, refined workmanship

Stable power, accurate temperature distribution

2 years warranty

V160M PLUS 50MM-160MM (2"IPS - 6"IPS)

Comact and lightweight

Precise pressure indication

Easy and quick operation

2-years warranty

- How could we select the right equipment for our project?

- Riyang could offer a variety of pipe fusion machine size up to 3000mm O.D. And each machine has the model number that indicates the maximum pipe size it can fuse. For example, butt fusion machine V630 could fuse maximum pipe 630mm O.D., and from the specification chart, you could always find the minimum size it can fuse. If you have specific requirements for your projects, please consult with Riyang sales.

- How long should it take to make a fusion joint?

- Time needed to make a fusion joint depends on the welding norms, pipe material, pipe diameter, pipe wall thickness and operator experiences.

- How much temperature on the heater surface needed to butt fuse the pipes?

- It varies depending on the pipe material and welding norms. Please consult the pipe manufacturer`s recommended parameters.

- Why the heater surface temperature is different from that shown on the digital temperature control?

- The digital temperature control indicates the internal temperature of heater. Some heat is lost on the transfer of heat to heater surface. In this case, it is better to use a thermometer to check the surface temperature of the heater. Use this as reference to monitor the heater temperature during the fusion process.

- How much material should be faced from the pipe end before melting?

- You could continue facing the pipe ends before the continuous and even chip comes out from the both pipe ends.

- What should we do after facing the pipe ends?

- You should always remember to remove all shavings from the fusion area and wipe the pipe ends with a clean and non-synthetic cloth.

- How could we calculate the soaking time?

- The proper soaking time varies depending on the pipe material, pipe diameter and wall thickness. You could always find the soaking time from Riyang operation manual for polyethylene welding machine.

- How could we calculate the cooling time?

- The proper cooling time varies depending on the pipe material, pipe diameter and wall thickness. You could always find the cooling time from Riyang operation manual for polyethylene welding machine.

- After welding, could we lay down the jointed pipes on the ground for cooling process?

- You are not allowed to lay down the jointed pipes on the ground after fusion welding. The jointed pipe should stay in the machine with/without pressure (according to different welding norms) until the cooling time ends.

- What is the power needed for Riyang pipe fusion equipment?

- When using a generator, the power recommended by Riyang is 1.5times as that of the pipe fusion machine. The machine`s power is displayed on the specification label on the top of hydraulic station.

- If the pipes are not properly aligned, what should we do?

- Before butt welding, the pipe ends must be rounded and aligned. A pipe roller support will give more helps in alignment and reduce the drag pressure. When the mismatch of the pipe walls is still out of local regulation, please adjust the clamping jaws by tightening down the high side until the pipe ends are even.

- What is the “drag pressure”?

- Drag pressure is the pressure to overcome the friction during machine carriage movement. It should e added to the total fusion pressure.

- How could we measure the “drag pressure”?

- You are always requested to measure the drag pressure with pipes stayed in the machine. Simply speaking, completely open the machine carriage, zero the pressure in the hydraulic system, close the pressure relief valve, then push the direction lever to maximum and gradually rotate the pressure regulated valve in a clockwise way until the machine carriage gets in motion. The current pressure shown on the gauge is the drag pressure. For more details, please refer to Riyang operation manual for butt fusion machine.

- *Name

- *Tel

- *Title

- *Content

Riyang fusion machine has been applied to more than 60 countries and regions in the fields of polyethylene pipe manufacturers, gas construction projects, irrigation projects, mining and civil installations, etc.MORE

- *Name

- *Tel

- *Title

- *Content